Q&A

Our team of experts are here to help…

Do you have questions on saddle fitting or saddle making or just wish to expand your own knowledge? You may find some of the answers below. Alternatively you are welcome to CONTACT US.

What is a template and why is it useful?

QA – What is a template and why is it useful?

Have you ever heard of a saddle fitter taking a “template” of a horse’s back? Or perhaps you’ve seen it in action.

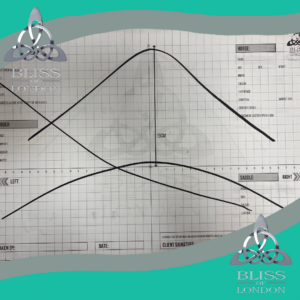

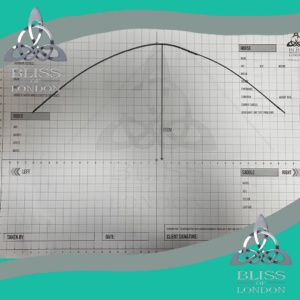

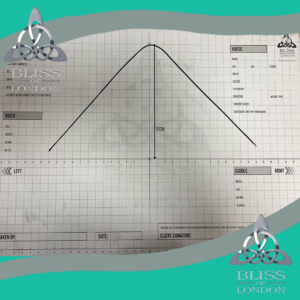

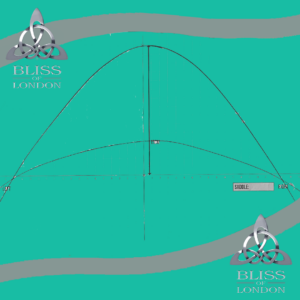

A template or a tracing—saddle fitters use this measurement to record the shape of a horse’s back. They can use this to really see what is going on with the horses back and see what they are working with. It will be used to compare on each follow-up visit so that over time it was show changes and hopefully improvement.

The first and main template which is taken 2” behind the scapula is the one that will be used to determine the width of the tree and in some cases this will be sent to the manufacturer if your saddle is being “made to template”

They are also likely to take measurements at T18 and the horizontal profile, these again will be use to compare and monitor the horses changes but also can be used to help discuss and determine tree profiles and gusset angles/depths.

No two horse’s templates are the same, it is fair to say we see some rather round ones but equally some that are taken can be extremely narrow, especially some the fresh “OTTB’s just out of racing and heading for a career change.

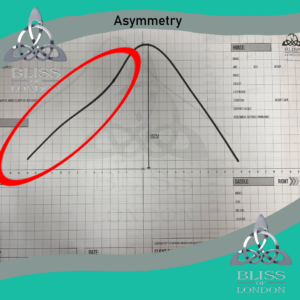

Visually, the template can show a lot about the horse. Their general muscular build and an asymmetry in the trapezius area.

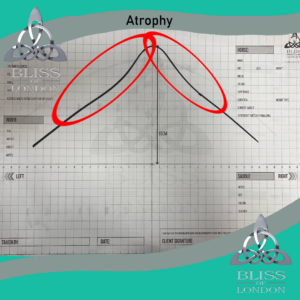

They can often answer the question as to why you may be having issues with your current saddle fit, muscle atrophy is often a main cause of this. We see various horses with significant dips behind the shoulders which is often believed to be ‘a horse with high withers’, but sometimes this is not true. The horse may be more developed on one side of their body for example and therefore pushes the saddle over to one side. This also of course causes a knock-on effect to various pressure points on the horses back which leads to soreness. This is why a template is so important as it allows a clear visual of what is going on with the horse that you may not even notice from the ground. After ruling out any unsoundness or physical issues, remedial saddle fitting may then be the answer to this, also a plan for the horse to ensure that they are working equally and correctly. It is advised for your saddle fitter to work alongside your veterinarian and/or qualified physio.

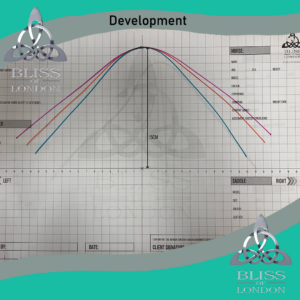

The template will show the progression, whether that be good or bad. If the horse is improving and working through and properly over its back this is likely to widen, however as horses become older you can often see a loss of topline. Young horses can start wider with ‘baby fat’ and then mature and as they are still growing in height can develop more of a wither height and shape to then again over time widen with muscular development. Weight is of course a key factory as well for fluctuations in width, summer grass can often increase, hunters being a great example who then become narrower as they become fitter through the season. But then also horses that are rested from competition more in the winter months on more hard feed often come through wider only to lose weight as the season progresses especially eventers.

As you can see in the image this same horse had changed by three widths within less than 1 year due to development in muscle and topline. This is why it is important for regular saddle checks.

Each horse becomes a whole picture project, and the template inevitably tells the story from start to finish.

Saddle pads Do's & Don'ts

Saddlepad Do’s & Don’ts

With so many different shapes, colours, and materials, it is often difficult to choose the correct saddle pad.

The primary function of a saddle pad is to absorb the sweat and grease from the horses back and therefore protect the leather panels on your saddle, not actually for adding that bling and sparkle!

But how about the fit? The fit of your saddle pad is very important.

Thickness is key, whilst we all love the tactile feel of squishy memory foam pads, they are not always a good additional to a well-fitting saddle and you should really speak to your fitter if you particularly want to be using these as they ‘could’ potentially change the balance and tightness of your saddle. In the same way that wearing extra thick socks in your boots can make then uncomfortable. They can be useful on perhaps rehab cases or maybe saddles that don’t fit particularly well initially. Ideally a regular thickness cotton pad is the best advice to use with a saddle that fits.

Sizing, don’t use a saddle cloth that is too small or short, this then creates a ridge beneath the saddle at the back which can develop excess pressure from both the saddle and your weight also. When tacking up, do make sure to check that both the front and the back of your saddle pad is visible and there are no overlaps. Always lift your saddle pad up into the channel of your saddle so that it does not pull tight across the back.

The shape of the saddle pad is also just as important as the size. It is generally not recommended to use a dressage saddle pad with a jump saddle and vice versa. This is because they are designed for the longer more straighter cut flaps and won’t have enough forward cut. A jump cloth will not be long enough for a dressage flap and in trying to get the girth through the loop could pull it down tight across the withers.

Material – ideally 100% cotton is the best as this will be the most breathable, be aware that the more foam or synthetic fillers it has the less breathable and more likely your horse will sweat more. Whilst there may be other factors causing your saddle to slip, one of the first things you should check is the material of your saddle pad. Silk or satin style saddle pads, although they are nice to look at, they do not provide much grip. However, a non-slip pad isn’t an answer to bad saddle fit. They are incredibly ‘grippy’ and therefore grip and rub against the horse’s hair and create sores.

It is quite clear that the ‘matchy matchy’ craze is here to stay, the overall look and colour of the saddle pad is considered important to most of us! But there are a few things that you should consider when you next grab your favourite saddle pad out of the tack room. The binding or the detail on the saddle pads can cause rubbing or sores. The edges can become rough, or now more commonly we see saddle pads with rope detailing around the edge which continue around the whole girth area. The girth will then sit over this and cause a decent amount of pressure. Just be aware of how your pad fits under your saddle and not just the look!

Velcro tabs – the positioning of these has improved but make sure the join of the tape is forwards of the cloth and not sitting directly under the panel of your saddle adding to pressure. If you don’t use them, unstitch them in case they get trapped underneath.

Another rising issue is the memory foam collars that are more commonly being introduced in saddle pads, which replicate the Velcro d-ring tabs. These can create a level of unnecessary pressure, if not positioned forwards of the panel.

Finally, a reminder – you should always make sure that the saddle pad is pulled up properly into the channel of the saddle, particularly at the front, before you girth it. If the saddle pad is lay flat across the horses back, this will become tight and cause pressure across the horses’ withers.

If in doubt with the fit or what to buy, then please ask your saddle fitter for advice as they will be the most informed to help you. Please note, this article does not cover remedial solutions to the saddle fit. This may be an up-and-coming topic soon.

Do you struggle to find a jump saddle with more forward flaps to accommodate your legs?

Question: Do you struggle to find a jump saddle with more forward flaps to accommodate your legs?

We come in all shapes and sizes, the typical tall and skinny dressage rider type, the female forward rugby player type, the Kylie Minogue petite jockey or as we like to sometimes call our horses in show condition i.e. chunky monkey type.

This is where the build of the flap could potentially need to be longer, shorter, straighter, or more forward; or the placement of the block can be altered.

There is always the option to do longer or shorter flaps, but before we throw in the height conundrum, we need to consider the length of stirrup that is used. It is typical for dressage riders to go for the longer position but in some cases, riders are maybe new to dressage and feel unbalanced having only ever been in a GP or Jump saddle. Riders with arthritic or hip issues often will find it more comfortable to be in a shorter stirrup position.

It is far easier to demonstrate the angle scenario with Jump saddles. Another pet hate is this “hip to knee” measurement what nonsense!

So, take for example you are William Fox Pitt tall, long legged, experienced, eventer rider you are going to have a short stirrup length (in his case otherwise he could probably tie his legs together underneath!) so yes you are going to need a more forward flap probably even x2 more forward and at what we term as 9 o’clock position. However, you are the same build and just switched from dressage to jumping so the angle of your leg will be much less and therefore the most forward point of your knee will be lower down requiring a more 8 o’clock forward flap.

Just because you are tall, does NOT mean you need a bigger seat; you need a more forward flap to accommodate your leg length not the size of your backside. As the years have gone by, this was however often a solution when manufacturers didn’t offer more forward flaps, which is why you may still hear it banded about. In more recent years thankfully our understanding of saddle fitting and manufacturing has increased advanced for benefit both the horse and the rider.

Your saddle fitter will be able to advise you on this and liaise with us with regards to any custom build needed. Please note you DO NOT need a larger seat as we are sometimes told!!

Why choose us?

Question: Why choose us?

BUYING WITH CONFIDENCE

With so many saddle brands on the market – why buy a Bliss or Loxley saddle?

Well firstly we would like you to have the confidence in our brand.

Whilst Bliss is a relatively young company in the grand scheme of saddle history, it grows from strength to strength each year, which must indicate we are doing something right! When choosing the right saddle, your choice of brand may depending on many factors

- Fit for your horse should always come first

- Fit for yourself is equally important

However confidence in committing to the purchase should come from the following:

- A knowledgeable fitter who is not simply a ‘rep’, who understands your needs and you can work with going forwards, as your horse develops.

- A company/brand who stands by their product with a warranty

- The knowledge that there is a repair agent in your country and the saddle doesn’t have to be sent back to the manufacturer should there be an issue

- A brand that has fellow equestrians at the heart of its ethos

- A brand that looks to continuously research and develop new products

- A brand that is approachable to ask questions

There are many “sales” people within the saddle fitting world and not always will they have your best intentions at heart. We choose to work with independent fitters who will often carry multiple brands of other saddles so that you have a choice. As you are paying for a visit fee, if on the unlikely occasion between you, you are unable to find anything that fits or you like, there is no pressure to ‘get the sale’ as their visit costs are covered.

With over 20 years in the saddle business I have seen many saddle companies come and go. Whilst everyone has to start as we did, there is always a risk that a new innovative design, may not actually stand the test of time, or perhaps the new company doesn’t succeed and then what happens to your warranty or how easy is your saddle to sell on in the future.

Do your homework: ask questions, check reviews

Where can I find the serial number?

Question: Where can I find the serial number?

Whether you are looking to purchase a second hand saddle or wanting to check the specs of your current one, the serial number can tell you some key information about your saddle.

When you receive your new Bliss of London or Loxley saddle, it will come with a swing tag.

This will tell you the serial number of the saddle, the seat size, and information on how to care for your saddle.

It will also include details on how to get your new saddle registered for you to validate the warranty.

All our saddles are also stamped with the serial number.

We are often asked how to find this..

Firstly, you need to determine whether your saddle is a Twinflap or a Monoflap.

If it is a Twinflap, the serial number will be located on the left sweatflap.

If it is a Monoflap, the serial number will be located under the left skirt.

If you are wanting to know the specs of your saddle, simply contact us with your serial number. If it is just the seat size and the width that you were wanting to know, then the last few digits of the serial number can tell you this. The serial number will also have an ‘L’ or a ‘B’, ‘L’ for Loxley and ‘B’ for Bliss.

For example, you may see ‘ 22954L175MW ‘ – The L175MW tells you that the saddle is a Loxley saddle, it has a 17.5” seat size and was set to a Medium Wide when it left our factory.

Please note: We cannot guarantee the width has not been altered since it left the factory.

We hope this information has been helpful in finding and understanding the serial number on your saddle.

If you have any further questions, our team at Bliss are happy to help over at register@bliss-of-london.com.

What tree does my horse need?

Question: What tree does my horse need?

What tree does my horse need?

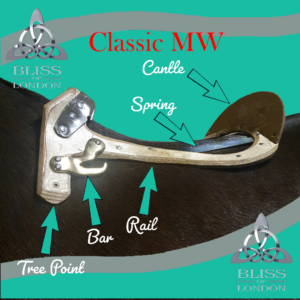

Trees, as we regularly say, are the foundation or ‘chassis’ of any saddle. It is imperative that the tree mirrors the shape of the horses back not only in width of the points but in the pitch of the rails and horizontal profile too. The tree distributes the weight of the rider through the padding of the panel.

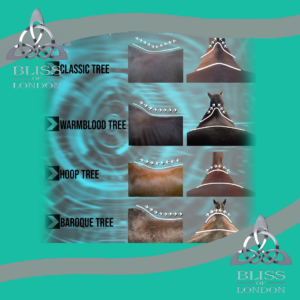

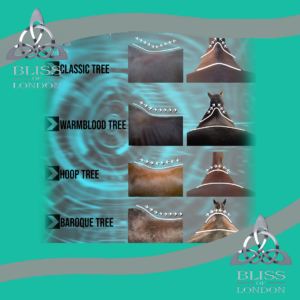

Whilst some manufacturers only offer one tree option, others that are more known for custom made saddles will have many. We offer the Classic, Warmblood, Hoop, Baroque, Close contact, Pony, and several others. Generally, they are specific to breed types/profiles but of course that is not always the case. As we have talked before about the twist and rails will be relative to the tree profile.

As you can see in the image the comparison between a Medium wide Classic and a MW Baroque both are a 90 degree angle however you can see for a horse with a particular broad wither that there is much more distance in the pommel/head area to provide more clearance, whereas a TB for example, would not need such clearance.

What happens if the wrong tree is used? Ultimately your horse will not be as comfortable as they could be and potentially this could be hindering their performance or even worse causing pain leading to behavioural issues. Some horses of course are stoic, so you may see no signs at all.

Our adjustable tree is moulded from the Classic model and morphs into the Hoop as the bars become wider. We will shortly have a new adjustable available based on the Warmblood profile.

Any saddle fitter that chooses to sell our saddles will fully understand the tree options available and be able to assess what is needed for you horse. In some instances, fitters will even carry the bare trees to be able to show you the differences on our own horse.

What does a custom saddle mean?

Question: What does a custom made saddle mean?

The term ‘custom saddle’ can mean a different thing dependent on who you ask. You can have pink stitching or blue welting, but what about the fit for the horse, and the rider too!

Primarily a custom saddle should be about fitting the horse. Do you have a tricky to fit horse? It may be that the tree is incorrect for that specific horse’s profile.

The tree forms the framework as it is almost like the ‘chassis’ of each and every saddle. This is why it is so imperative that the correct profile is selected by your saddle fitter. The tree must be able to mirror the shape of your horse’s back to distribute the weight of the rider effectively to reduce pressure.

In conjunction with the tree profile, the use of a front and back gusset, for instance on a panel, can help provide support for a horse to distribute weight-bearing surface to achieve clearance and balance. Panels can also help compromise for those heavier set breeds.

What about the girth strap arrangements? Straps can be as standard – Monoflaps typically have two straps whilst twinflap saddles usually have three straps, but sometimes there are exceptions for those trickier fit horses. This can easily be incorporated into your new custom made saddle.

Once the fitting of the horse has been covered, we then draw our attention to the rider. From seat sizes 15″ to 19″ and an optional Performance seat for extra softness. Our saddles have long/short/forward flap options for tall and petite riders alike. We offer custom adjustments to meet your own individual requirements, such as the leg placement. Being tall doesn’t necessarily mean you need a bigger seat, you need a more forward flap to accommodate your leg length. It is your hip/knee angle and stirrup length that ultimately affects the positioning of the roll and forwardness of the flap to provide the most appropriate support. This is why we offer the choice of a 1″ or 2″ more forward flap at 8 or 9 o’clock.

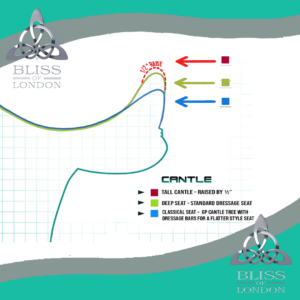

Seat types – let’s not forget that these vary; dressage saddles have higher cantles so have the deepest of seats, a GP in usually a midway point and then the Jump seats are much shallower coming as flat as an Eventer saddle which allows for much more freedom and movement in the seat. So the same seat size is not going to give the same feel or support in different models and sometimes these can be changed or mixed depending on what you prefer. It is not uncommon to make dressage saddles with GP cantles!

Once the rider and horse is happy – we then move on to the overall look of the saddle! We take pride in our leather selections, the unique suppleness of the Bliss of London and Loxley by Bliss saddles are available in Black, Cocoa, Claret and Cognac.

With custom saddles you also have the choice of selecting your colour of welting or sometimes known as piping. The is the seeming that runs either side of the seat and around the back of the cantle. Furthermore, you also have the choice of feature stitching colour, and if you would like to choose something even more unique then there are lots of cantle designs to choose from too!

Am I better to have a wool or a foam panel?

Q: Am I better to have a wool or a foam panel?

A:

As a rule, so long as the saddle fits, whether it is wool, foam or even air should not matter.

However, wool is without doubt the most versatile material to work with, not only will a wool panel be flocked to fit your horse in the first instance, but it has the properties to be adjusted accordingly at subsequent intervals.

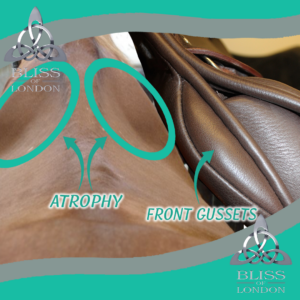

If it is a young horse the balance front to back is likely to change as he is still growing, saddles with front and back gussets allow the freedom to add or soften to achieve this. Perhaps he is an older horse and muscle atrophy is starting to appear, again wool panels can be flocked independently left to right to achieve a better balance. There are so many examples of where wool flocking really does come into its own.

This is where foam panels have a downside, as there is no adjustment.

The saddle may fit well initially however when your horse changes shape what can you do? It may be possible to have new panels made, however as most of these saddles are associated with continental brands this often means lengthy time frames shipping saddles back to Europe. Or mostly likely this is where you will see an endless use of adjusta/shim/riser pads being used to accommodate a poor fit.

All reputable saddle fitters will have the skills to be able to do flocking adjustments on a saddle, this is part of the SMS saddle fitters’ qualification.

Any saddle should be checked for fit regularly with potential flocking adjustments needed and can be reflocked completely throughout its lifetime when needed. The use of a front gusset for instance on a panel can help provide support for a horse with atrophy and then over time will allow development and the wool can be softened. In some instances, foam panels are often converted by preference to wool.

Wool is a ‘natural’ fibre and has remarkable properties. It will mould to the shape of your horses back, it is proven to be shock absorbing, can help to reduce friction, absorbs up to 30% of its own weight in moisture and draws heat away from the horses back. Not only this but it is bio-degradable and sustainable unlike foam. Using British wool supports British farmers and the environment.

– We would like to hear your comments and any further questions on this topic.

Stirrup bar up or down?

Q: Stirrup bar up or down?

A:

Stirrup bars up or down!

In response to a few social media posts recently regarding this topic it seemed an apt subject to do a short article on.

Traditionally stirrup bars always had what we call a ‘thumb bit’ the flexible piece at the end that can be flipped up or down but why?

The correct way to use these is always in the ‘up’ position, as the bar itself is straight having the thumb bit at the end prevents the stirrup leather from sliding off in ‘normal’ riding situations. Dressage as we know should be 4 feet on the ground relatively speaking! However, when jumping the whole angle changes and the bar very much goes into a take-off position which could easily result in the leather sliding off at this point. So, the thumb bit will prevent this.

So why do most riders prefer it down? Mainly due to the fear of it not releasing. Should the worse happen and your foot was stuck in the stirrup whilst falling off you want the stirrup leather to slide of the bar to release. So, the key to all of this is to ensure with regular maintenance as you should for all the equipment that you use, that the bar is flexible and easily flips both up and down. Removing dirt and grime and perhaps treating with a little oil/WD40 will help to do this.

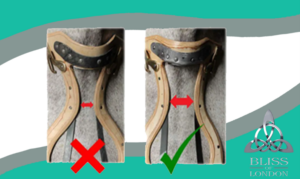

OK so why not just leave the bar down all the time? Firstly, due to the above comment that it may allow the leather to slide off when not intended but also as importantly lengthening the stirrup bar can cause pressure against the horse.

You will see in the images all stirrup bars angle with the profile of the tree (which is why it is SO important to have the correct tree profile in the first instance) if they were angled outwards then your leather would be likely to slide off. But as the length of the bar increases so does the closeness to the horse which can cause unnecessary pressure through the panel.

Jump/GP bars are generally shorter in the body as the rider has a more forward position. With dressage saddles requiring the leg to be more underneath the rider, the body of the bar is extended slightly to provide a setback position.

Partly due to this misconception of how to use bars, more commonly, most used now are the hook bars, which provide sufficient support with the small hook to prevent leathers sliding off in normal circumstances however will let the leather slide off in the case of an accident.

Do’s and Don’ts

DO

Always keep your stirrup leathers run up, when leaving the stable, walking through gate ways or arenas. Thankfully we don’t see too many ‘accidents’ but when a stirrup bar is bent it is usually when an iron has been caught on something ie a door bolt and yanked the bar outwards. Believe me, bars do not just magically do this on their own! Our stirrup bars are tested to 600kg on each bar that is produced.

DON’T

Ever let anyone bend out your stirrup bar

Equally if your stirrup leather is too loose with too much room behind the bar, speak to your saddle fitter as this may be a flocking issue, so don’t ignore this!

It is not ideal to put any straps/fittings onto your stirrup bar, stirrup bars were only designed for stirrup leathers. This is more of an issue when we see the straps taking up the space on the bar and not allowing room for the leather to lie correctly which can cause the leather to slide off in some instances.

How should I store my saddle?

Q: How should I store my saddle?

A:

Your saddle is probably the most expensive item you are likely to purchase after your horse, so it makes sense to follow a few simple guidelines to make sure it doesn’t come to any unnecessary harm.

STANDS – Probably the most common seen issue is storing saddles on the metal saddle racks. The narrowness of these rails can cause significant imprint into the wool flocking on the panels, which can then in turn affect the pressure against your horses back.

This can be simply remedied by using foam pipe lagging along the rails to spread the weight, which is cheap and effective, this can be purchased from most DIY stores.

In additional to this further pad out the stand by using your saddle pads over the top of the stand as well.(or good use for your old collection of unused saddle pads)

Ideally the best racks are ones that have flat sides to protect the panels or even the single pole racks but be careful the saddles don’t rock and fall off!

Don’t stack saddles! Not only does this put unnecessary pressure on the underneath saddles but panels sat onto of cantles can again cause serious indentation.

Another simple oversight is often tack room walls if made of brick can be quite rough, slamming the saddle forwards on wall fixed racks can scratch the front facings of the saddle, so a little protection either side from sticky foams or even old pieces of carpet help protect.

OFF THE RACK – try where possible not to put the saddle pommel down on the floor, again this can cause scratching damage to the front edge facing of the saddle. But more commonly if left like this for longer periods of time especially with jump saddles can cause the knee pads to fold back and crease.

COVERS – Always cover your saddle! Honestly how many of us don’t? They are so many reasons that this is good for your saddle. Thankfully only the other day I had finished riding and had put my saddle on the door with the lovely thick fleece cover on and then my mare kindly knocked it off. The horror of that thud sound when it hits the ground. Luckily the cover had protected it from any scratches and dents.

Barn cats are also notorious for loving to have a good scratch on leather, I bet there have been more seats replacements due to animal bites and scratches than actual wear and tear.

Temperature changes can have great effects on leather, so using a good quality fleece cover will help to stabilise this and wick away any excess moisture to prevent mildew and protect from outside conditions.

So a cover will with you general overall protection while transporting and storing from knocks, bumps, rain and spillages

STIRRUPS – Long gone are the old standard stainless steel stirrup irons, so with an ever increasing array of cheese grater options, don’t forget the scratching this can cause to your saddle. Stirrup covers are now readily available to protect or an old pair of socks can do the same job.

Don’t expose to long periods of strong sunlight as this will strip the colour from the leather

Don’t expose to excess heat and this will dried out the goodness in the leather

Don’t be panicked by a white grease appearance on the leather after exposure to heat and then coolness as this is the grease solidifying which is a good sign of leather quality.

Don’t dry next to a heat source if it has got soaking wet. Allow it to dry naturally and then condition afterwards

Please see our other link for advice on cleaning.

Saddle Twist explained..

The Twist

‘Twist’ how can one word cause so many opinions and controversy! The rider initially views the twist as the visual distance between the skirts and then secondly as to how the saddle feels to sit in.

Here you can see that there is a clear difference in the width measurement due to where the skirts are machined, despite being the same model built on the same tree!

The twist is totally dependent on the build/style of the tree itself. Many continental saddles are built with the rider in mind more so than the horse and therefore the pitch of the rails on the tree are much steeper in order to emulate a narrower twist for the rider, however as we know this is not always the best option for the horse, unless perhaps you have a OTTB.

You can see here that in the left photo, the rails are much closer, creating a narrower twist for the rider. In comparison to the right, where the rails are wider apart therefore allowing for the panel to be supported by the rails for a broader gullet.

The pitch of the rails on the tree must always form a parallel to the horses back in order to avoid any uneven pressure, but of course this isn’t always the ideal feel for the seat. If a rider is to be concerned about the fit and comfort of the horse, then in some circumstances they must compromise on what they would prefer.

It is often more a case of what they have been used to, a little like a favourite pair of shoes and then something new takes a little getting used to. But the width of the horse/tree profile has an influence on the twist as well, my advice to those that always want a narrow twist is don’t ride an extra wide horse!

As the feel of the twist is the degree of hip joint abduction and flexibility of the hip adductor muscles, being able to reduce this stress can be of benefit, this is where the monoflap saddles come into play as there is physically less under the leg and the skirt is pitched at a steeper angle it can help to make ‘the twist’ or at least what the rider is interpreting as the twist feel narrower.

And don’t forget, not all riders prefer a narrower twist, we are all anatomically different and while it is well reported that women have a wider distance between the seat bones than men, this is ‘in general’ and there is still great deal of overlap.

We have developed the Slimtech twist, which is a unique forming of the seat in the twist area that does help to alleviate some of the width for those that prefer a narrow twist. This more common on dressage saddles than Jump.

The design of the interchangeable bars on the adjustable trees are specifically so that as the head broadens for the width it only widens the trees points and has less influence on the pommel/twist area.

Saddler or Saddle Fitter - The great confusion!

Q: Saddler versus Saddle fitter – the great confusion!

There are always regular posts on forums regarding saddle fitters, however one of my biggest frustrations is them being refer to as ‘saddlers’. Now this is not the fault of the equestrian world if the difference is not explained to them! However there is a big job role difference here – so listen up!

A Saddle Fitter is someone who can check an existing saddle fit and make flocking adjustments if need be. Most but not all will also sell new or used saddles. They will most likely run their own business and are classed as ‘independent’ carrying multiple brands of saddles with no allegiance in particular to any one brand. This will give you a better selection of saddles in order to find the correct option to suit your horse and yourself if looking to purchase a new one. Saddle fitters should not be there to simply sell you a new saddle. They will also offer after sales service, with regular checks and adjustments.

Saddle fitters are there to provide advice in the same way you would expect to receive it from your vet, physio, farrier or trainer and will often welcome the opportunity to work in conjunction with them to help resolve problems and issues for the greater good. A slipping saddle for example could be anything from ‘a saddle issue’ to a horse with muscle atrophy, lameness, rider stiffness or even imbalanced hoof issues. Your experts are best when working together as a team. A saddle fitter will not give a veterinary opinion but may suggest you consult your vet in the same way that you wouldn’t expect your trainer to give you saddle fitting expertise, unless of course they are qualified in both!

Whilst there are currently no legal requirements needed to offer services as a fitter (unlike veterinary etc) there are several recognised international INDEPENDENT qualifications out there. Not to be confused with the many ‘certified’ courses that are often a week long and self regulated by the saddle brand companies that offer them.

The Society of Master Saddlers (known as SMS) is the most recognised internationally. Look for the badge and note the difference between Master Saddler and Quailfied Saddle Fitter

Master Saddle Fitting Consultants (known as MSFC) is another independent qualification.

https://msfc.nl/en/saddle-fitting-course-goals/

Don’t be afraid to ask your fitter what qualifications they have, or perhaps they are currently training under the SMS towards qualification and will be receiving regular CPD, this is a minimum of a 3 year process.

And then we have Saddle Reps who are generally employed by the brand that they represent and therefore will not carry a wide range of saddle brand choice. If you purchase a saddle your sale will likely go directly through that company. They may not be able to offer assessment or any adjustments on other brands of saddles and the saddle fitting training may limited and less extensive than the above.

Saddle fitters and ‘reps’ are two very different entities!

Saddlers on the other hand have a very different role. A saddler is someone who can make a saddle, repair a saddle but is not necessarily be qualified to fit it, they may also produce other leather associated items. Within the trade/factory element of saddle making most saddlers will rarely leave their benches or get involved with fitting, however this takes nothing away from them as highly skilled craftsmen. Outside of the trade you have independent or rural bench saddlers who most likely have learnt their skills due to a background passion for horses.

Again there is no legal requirement to be able to call yourself a ‘saddler’ but the SMS offers a route from apprenticeship to full Qualification as a Master Saddler.

https://www.mastersaddlers.co.uk/training/craft-how-to-train/craft-training-providers/

https://www.mastersaddlers.co.uk/training/craft-how-to-train/craft-training-providers/

Finally you may be one of the lucky ones that has the best of both worlds and your go to “saddle person” has taken the time to train and qualify as both a Qualified Saddle Fitter and a Qualified Master Saddler!

Do pony saddles have smaller flaps?

Yes they can do. All models of saddle whether dressage, jump or GP all have different flap sizes depending upon the seat size. They is usually approximately 1/2″ difference between each seat size.

Pony saddles can be more complicated due to the size of the rider. Sometimes a 16″ pony saddle for example may be used by a small adult who would perhaps need a longer flap than smaller child. So as we build custom made saddles you can discuss the most appropriate flap length with your saddle fitter.

We would like to hear your comments and any further questions on this topic. We are readily available for saddle fitting advice, so please feel to contact us with any subjects you would like us to focus on.

How to determine seat size

Seat size is a widely debated subject.

The seat size of a saddle always relates to the size of the rider. Much to contrary belief it is only the size of their behind/booty/backside whatever your choice of term and NOT leg length.

It is difficult to gauge but approximately based on English sizes a 10 would be a 17″ and a 12 a 17.5″.

If a rider is tall then the best way to custom build a saddle is to have a more forward flap or longer flap, not to extend the size of the seat itself. If a rider is sat in a saddle that is too big for them there are unlikely to have the correct balance and support from the seat.

Our seat sizes range from 14″ through to 19″ in half inch increments

We would like to hear your comments and any further questions on this topic. We are readily available for saddle fitting advice, so please feel to contact us with any subjects you would like us to focus on.

Both my trainer and I ride my horse, how can I find a saddle to suit us both as we are different sizes?

Finding a saddle to suit more than one rider is more common than you may think. The first point to remember is that it must be fitted to the horse primarily. (image rider sat on cantle)

The main factor is whether you are able to share the same seat size, if not, it is likely you will have to go to the larger seat. It is imperative that a rider sits in the centre or balance point of the saddle so squeezing a rider into a seat size that is too small will put excess pressure at the back of the cantle and ultimately onto the panels under the cantle, as well as putting the rider out of balance. Your saddle fitter will advise as to the maximum length of panel/seat that your horse can take without impinging past T18.

(image diagram T18)

The use of Velcro blocks is now a huge advantage to allow the shorter rider a more effective support if compromising with a larger seat by bringing the block closer towards the leg. (image Velcro dressage block) Velcro blocks also allow repositioning of height and angle for different stirrup lengths and the angle of your hip to knee. It may be that even a different style and depth of block is beneficial for each individual rider’s preference. They can also be requested on back blocks where sometimes riders are unsure whether they will benefit from them or find them interfering. Reputable manufacturers use a premium quality of hook and loop fastening so it is unlikely that they will fall off whilst riding however replacement blocks or additional sets can always be purchased separately. (image back jump Velcro block)

If we are looking at a Jump saddle then a forward flap is also another option to consider.

(image Jump forward flap)

We would like to hear your comments and any further questions on this topic. We are readily available for saddle fitting advice, so please feel to contact us with any subjects you would like us to focus on.

Am I better to have a wool or a foam panel?

There is no doubt that foam panels have improved no end in recent years, to the extent that even custom made foam panels are available in some of the higher end brands. However this is great when you are buying a new saddle for your horse and it fits there and then, but what happens when you have a difficult to fit horse or your horse changes shape, as most do at a later date?

(pictures Foam panel v wool panel)

This is where wool comes into its own, not only will a wool panel be flocked to fit your horse in the first instance but has the properties to be adjusted accordingly at subsequent intervals. If it is a young horse the balance front to back is likely to change as he is still growing, saddles with front and back gussets allow the freedom to add or soften to achieve this. Perhaps he is an older horse and muscle atrophy is starting to appear, again wool panels can be flocked independently left to right to achieve a better balance.

(picture of horse with atrophy) (picture of front gussets)

A panel can be reflocked completely throughout its lifetime by a saddler and in some instances foam panels are often converted by preference to wool.

(picture of saddler flocking panel or video)

In addition, wool is a ‘natural’ material and has remarkable properties. It will mould to the shape of your horses back, it is proven be shock absorbing, can help to reduce friction, absorbs up to 30% of its own weight in moisture and draws heat away from the horses back.

We would like to hear your comments and any further questions on this topic.

What does “spring tree” mean on a saddle?

A spring tree is the classic style of saddle tree used in English riding saddles. The tree is constructed from Birch plywood and reinforced with Spring Steel that is fixed onto the rails of the tree and through the centre. Hence the term Spring Tree. The spring steel not only strengthens the tree but also allows the wood an element of flexibility. The flexibility in the tree can range from soft to firm dependant on what angle the layers of 1.5mm birch are laid up giving a number of choices for saddle makers.

First designed and used in Walsall UK in the 1940¹s it has been estimated that to date there have been over 3 million spring trees produced for saddles world wide. Although the principles remain the same the technology and understanding of design has evolved greatly over the years. The British Standard BS: 6635 2003 states that Wooden Spring Saddle Trees must be produced to the latest engineering standards and with a symmetry tolerance of + / – 2mm. Many of the worlds leading saddle makers will produce on Wooden Spring Trees.

Old fashioned Rigid trees, which are still common in polo saddles and some of the less expensive Indian-made saddles, are all wood without any spring steel reinforcement; they¹re heavier and don¹t have the flex a spring tree offers.

Plastic Injection-moulded trees or ‘polymer’ can be flexible or rigid but do not also offer the degree of different profiles that can be offered with wooden spring trees.

What are serge panels?

Serge panels are an alternative to leather for the underneath bearing surface of a saddle. This is an age old traditional way of panelling still used today in side-saddles, which in recent years has seen a come back.

Serge is natural material which is made of wool. Wool is the best material to absorb moisture and then disperse this naturally over a period of time. Not only will it make your saddle lighter in weight, but it is also kinder to your horse’s back. (image of panel)

Many customers report significant improvement in their horses shape and movement once they start using serge.

It helps to eliminate slipping and as it is extremely soft and kind to their backs.

It can also be suitable for ‘cold backed’ horses. If your horse shows signs of tension when you put the saddle on and/or mount, this extra softness and relative warmth in comparison to leather panels in cold conditions can help to ease this. (image Loxley’s saddle on back)

Serge is very popular in endurance riding, as the rate of heat and moisture absorption is far quicker than leather, so the back is kept cooler for longer. Hence making this particularly beneficial in warmer climates.

Most commonly saddles that have serge panels are still used with a saddle cloth which helps to keep it clean, however it can be used without if required.

Cleaning is often the largest worry for riders considering serge, however if used with a pad then this is a simple as using a soft brush to remove any loose hairs or a small suede shoe cleaning brush for anything a little more stubborn. The material requires no conditioning or treatment and as with leather allow to dry naturally if it does get wet.

(image cleaning suede brush)

For your saddle fitter, a serge panel can have the flocking regulated with an awl directly through the panel which is not possible with leather.

(image of awl through a panel)

How should I care for my Bliss Of London product?

Bliss Of London products are made from high quality English Leather, most of our leathers are Aniline which means they have an untreated surface which makes them beautiful to touch and absorb character. Please use a natural solvent free leather balm to keep your leather soft and supple. Avoid leather cleaners as these usually contain solvents or chemicals that can pul the colour out of the leather. Leather products should stand the test of time when treated in the appropriate manner. Please see below, a list of Do’s and Don’ts.

Do:

- Regularly remove dirt and treat your saddle with a natural balsam

- Store your saddle in a damp free climate

- Let your saddle dry naturally

- Use your Bliss saddle cover when not in use

Do Not:

- Use leather cleaners or heavy oils

- Use solvent based leather care

- Hose/soak your leather

- Scrub your leather

- Stack your saddle (the panel should mould to your horses back, not what it is stored on)

This is not a fully comprehensive list but a few pointers. We have our own Bliss Of London leather care which is available from your saddle fitter or Bliss-of-london.com. For more information please refer to the Leathercare section of the website.